Description

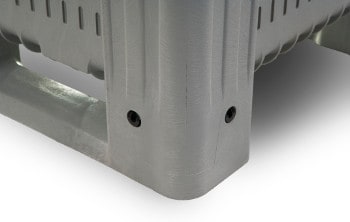

The Ace container was designed to meet the most rigorous of applications. With its innovative one-piece design, the Ace will work well in the Agriculture, Food Processing and Industrial industries. The Ace containers are temperature resistant, UV resistant and can be stacked 10 high. The unique molded in ribbing will give extra sidewall strength and prevent bulging of the bin. Because of the strength and durability of the bins, Decade bins are extremely cost-effective vs. wood and corrugated.

Specifications

| Specifications | English (U.S.) Units | Metric Units |

| External Dimensions | 48″ x 40″ x 31″ | 1,200 x 1,000 x 787 mm |

| Internal Dimensions | 45″ x 36.5″ x 25.75″ | 1,143 x 927 x 654 mm |

| Weight Capacity | 1,000 lbs. | 454 kg |

| Internal Volume | 190 U.S. gallons, 25.4 cubic feet | 719 liters |

| Stack Load | 10,000 lbs. | 4,536 kg |

| Tare Weight | 74 lbs. | 33.5 kg |

| Stack Height | Up to 10* | |

| Truckload Quantity | 150 | |

| Material | High-density polyethylene structural foam | |

Recommended Safe Use of harvest Containers

The Ace Container is ideal for harvesting, transportation, and storage of produce and general material handling. The Containers are manufactured using resins and additives that have been fully tested and comply with FDA guidelines for direct food contact.

Product specification sheets are available and should be carefully read before the Containers are used. These Harvest Containers must be used per the product specification guidelines outlined in the literature.

Cleaning

The HDPE Containers can be cleaned using high-pressure washers or hot water steam cleaners.

Basic Safety Guidelines:

- Heavy objects should not be dropped onto the floor of the bin as they could damage the bin floor.

- Any unauthorized alteration or modification to Containers will void any warranty and may negatively affect the structural integrity of the containers.

- Containers with damage to posts should be taken out of service and recycled.

- When cleaning or sanitizing Containers, the resistance of HDPE to degradation due to contact with chemicals used should be reviewed. Contact us for assistance.

- Containers must not be pushed over onto hard surfaces.

Storage

Harvest Containers are virtually maintenance free, and can provide many years of service when maintained in accordance with guidelines. Containers are robust, made using materials that will withstand normal usage. Containers can be stored outdoors without plastic degradation due to our excellent U.V. and A.O. stabilization systems.

With our interlocking post and runner design, consistent dimensions, and dimensional stability Containers provide crucial improvements over wood containers in space utilization and efficiency

Harvest Containers should always be stacked on hard level surfaces. Stacks should be located in an area away from personnel activity. Unauthorized individuals should be kept away from bin stacks. Exercise caution when de-stacking Harvest Containers outdoors as rainwater could accumulate in the top bin.

Repair of Damaged Containers

Minor damage is simply repaired utilizing a hot air welder and plastic welding rod. The welding rod must be HDPE. For instructions related to bin repair, contact Decade Products.

Temperature Ranges

Containers can be used over a wide range of temperature environments and filled with contents that fall within these ranges – contact Decade Products for details.

Capacity and Stack Weight Limits

Containers have been designed to perform within specific maximum load capacities and stacking tolerances which are not to be exceeded. Please refer to your product-specific specification sheet.

Inter-stacking

For safe stacking it is important that load stresses are transferred in the designed manner. Containers have been designed with posts and runners that ensure optimum bearing of loads: for save usage – consult with us before Containers are inter-stacked with wood containers or other containers.